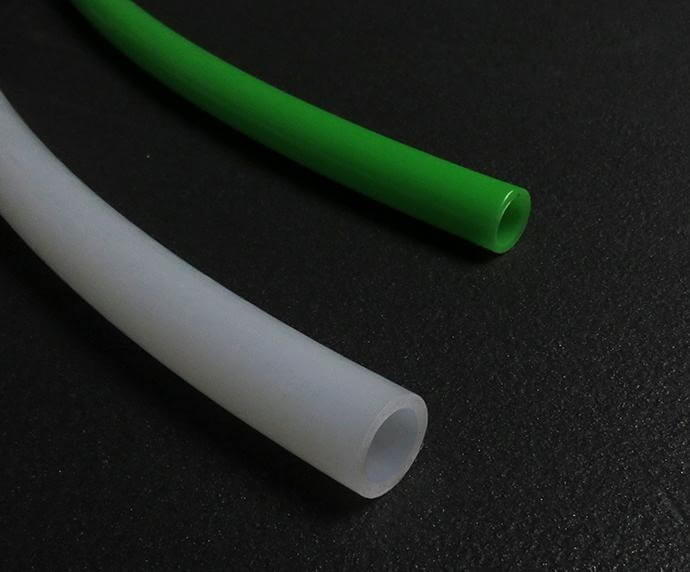

PE-RT Pipe

HydroHeat pipes are made from polyethylene of raised temperature resistance (PE-RT) that have unique molecular structure and crystalline microstructure, which provides excellent long term hydrostatic strength at high temperatures without the need of material’s cross-linking. The lamellar crystal structures are connected through amorphous polymer segments: the tie chains. This could be described as a kind of geometrical cross-linking”. Tie chains show extensibility and mobility and can absorb and dissipate energy.

HydroHeat pipes are produced according to the following international standards and specifications:

– DIN 16833/16834

– DIN 4721- 4726 (for pipes with oxygen barrier)

– ISO 22391

The outstanding flexibility and superior smoothness of the inner and outer surface of HydroHeat pipes allow the economical, safe and qualitative installation with no incrustations and low pressure loss. They are ideal for underfloor heating installations where very close bends are required.

Polyethylene PE-RT (DOWLEX 2344E) pipes with an oxygen barrier of five layers, suitable for heating. The oxygen barrier prevents the entrance of oxygen in the water circulation, so the corrosion of metal parts of the system is avoided. The oxygen barrier is achieved by using a special material (EVOH), that is situated in the middle of the wall thick- ness (5 layers).

Storage and Handling

Before using HydroHeat pipes, they should be stored in their original packaging under cover in order to prevent dust accumulation, avoiding long-term exposure to sunlight and damage. Do not use pipe which has cuts, deep scratches or gouges, kinks or crushed sections, evidence of grease, oil or noticeable color fading of pipe. All damaged sections should be cut and replaced.

Installation

The cut of an HydroHeat pipe must be done perpendicular to the axis of the pipe by a special pipe cutter. In order to achieve hot bending of HydroHeat pipe, it can be either heated by a hot air gun with a diffuser nozzle of controlled temperature, or by hot water circulating inside the pipe. Attention: the use of the open flame is forbidden. Care not to kink or damage the pipe. The maximum bend radius at 20°C should be 6 times the nominal outer diameter of the pipe. HydroHeat pipes can be connected with screw, press, and push fittings.

Heating

The linear expansion rate of HydroHeat pipes is approximately 19,5mm/10°C temperature change for each 10m of pipe. When installing long runs of pipes, allow 15-20mm in longitudinal clearance per meter of run to accommodate thermal expansion. Pipes must not be anchored rigidly or pulled tight between fixed points (i.e. manifolds-valves etc).